New Digital X-Ray Capabilities at EDT, Enhancing Fire and Mechanical Investigations

At Engineering Design & Testing Corp. (EDT), we’re continually advancing our capabilities to deliver precise, reliable answers to complex engineering investigations. One of the latest additions to our toolkit is our new digital X-ray equipment, which is already making a significant impact on the way we conduct investigations. This equipment allows us to dig deeper—both literally and figuratively—into the root causes of incidents.

Currently certified for use in Kansas, EDT is actively pursuing certifications in additional states to extend the availability of this advanced technology. As a portable system, the digital X-ray can also be used on-site, offering clients the flexibility of immediate analysis at the location of an incident.

Why Digital X-Ray?

Traditional X-ray methods rely on radioactive materials and film-based imaging, which come with challenges such as limited usability, time delays, and strict safety requirements. EDT’s new digital X-ray system eliminates these issues by:

- Using a non-radioactive X-ray source: Our new digital X-ray utilizes a high-voltage titanium element within a tube to generate X-rays, eliminating the need for radioactive materials. This innovation not only simplifies safety protocols but also allows us to operate without the stringent requirements of shielded environments.

- Delivering digital images, which removes the need for film development and allows for instant image analysis. The digital format also means we’re no longer restricted by the six-month shelf life of film.

- Offering flexibility with adjustable exposure and contrast, enabling a clearer and more detailed view of the subject.

This means faster, more efficient investigations and fewer logistical hurdles for our clients.

Digital X-Ray Applications in Fire and Mechanical Investigations

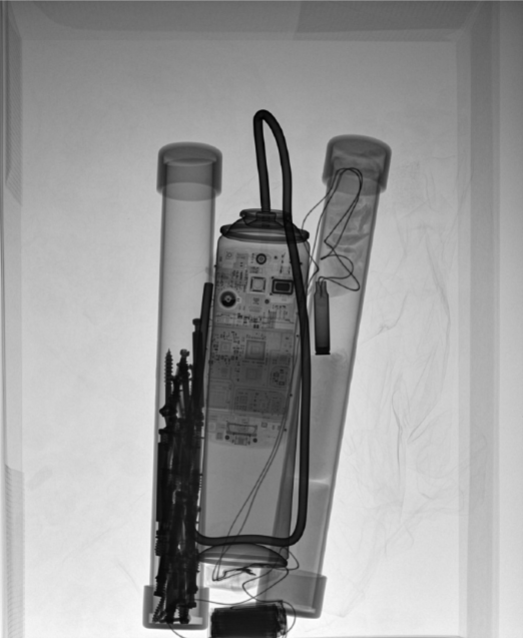

The digital X-ray system is particularly valuable in fire debris analysis. In fire investigations, it’s common to encounter a “blob” of melted materials where components like electronic parts, light bulbs, or gas valves are embedded. Previously, examining these blobs often required sending them to a third-party facility for X-raying, which could delay the process and complicate the investigation.

With our new in-house system, we can:

- Examine fire debris: Identify whether specific components (e.g., gas valves, light bulb filaments, or wires) are intact or show evidence of failure, such as arcing or melting.

- Evaluate mechanical systems: Determine the position of valves (open or closed) or the integrity of other components without disassembling them.

- Streamline processes: Reduce the time spent transporting materials to external labs, allowing us to provide answers more quickly.

For example, in a recent case, the X-ray system allowed us to confirm that a light bulb filament within a melted polymer mass showed no signs of damage, ruling it out as a cause of the fire. This ability to quickly rule in or rule out potential causes with precision is a game-changer.

Expanding Access and Versatility with Digital X-Ray

Not only is this system portable, but we’ve also ensured it meets all state safety and regulatory requirements. The portable nature of the equipment allows us to conduct on-site investigations, such as examining fire-damaged water heaters or HVAC systems, before bringing components back to the lab for further analysis.

Additionally, the system’s software enables advanced imaging features, including:

- Embossing: Accentuates high-contrast edges, making it easier to identify critical components.

- Colorization: Highlights electrical conductors and other important features, providing clearer insights.

- Sharpening: Enhances image clarity, allowing for more precise examinations of intricate details.

- Image Stitching: Combines multiple X-rays to create comprehensive views of larger objects or complex structures.

Who Benefits from Digital X-Ray Capabilities?

Our X-ray services are already being utilized by:

- Insurance carriers: For fire claims and loss analysis.

- Manufacturing companies: To investigate equipment failures.

- Attorneys and forensic experts: Seeking detailed examinations of critical components.

Clients can bring components to our facility, or we can travel to their sites for on-location X-ray investigations. This flexibility ensures we can adapt to a wide range of cases and client needs.

Advancing Forensic Engineering with Digital X-Ray

The addition of digital X-ray technology reinforces EDT’s commitment to rewriting the standard of excellence in forensic engineering. By investing in tools that save time, enhance accuracy, and reduce complexity, we continue to provide the dependable solutions our clients rely on.

Interested in learning more about EDT’s X-ray capabilities? Contact our team today to find out how we can assist in your investigation.

About the Author

Richard L. Ellsworth, P.E., is a Consulting Engineer with EDT’s Kansas City office. He earned his mechanical engineering degree from the University of Missouri-Columbia. Richard's background includes designing and testing wheel loaders, as well as research and development of lift designs, code evaluation, cost reduction, project tracking, document archiving, and finite element analysis (FEA) of components.