Understanding the Impact of Vibration on Equipment and Structures

When it comes to engineering problems, sometimes the smallest vibrations can lead to the biggest headaches. Whether it’s cooling towers rattling a building’s framework or ventilation fans wearing out long before their time, the ripple effects of vibration can cause serious operational issues, equipment damage, and even safety risks.

Vibration analysis—a specialty we’re expanding here at EDT—gives companies across industries a powerful tool to pinpoint where and why these problems are happening and to prevent them from coming back.

My journey with vibration analysis started years ago, analyzing vibration issues on maritime antennas. These are satellite communication antennas designed to stay locked onto a geostationary satellite as the ship moved through rough seas. The antennas needed a high degree of freedom to adjust to the ship’s movement but can be susceptible to specific vibrations on some vessels, leading to failures. I was initially brought on to figure out what was breaking, how it was breaking, and what tests could be done to strengthen the design. By using accelerometers on the antennas, we could diagnose issues caused by a ship’s unique vibration profile, advising shipowners on necessary repairs or design adjustments. This experience was foundational in understanding how vibrations impact structures.

With EDT, I’ve applied vibration analysis to help clients from various sectors address a wide range of issues. In this post, I’ll share a few real-world cases where vibration analysis has helped resolve complex problems—highlighting the ways EDT’s services create measurable value, whether it’s through extending equipment life, reducing downtime, or supporting rigorous forensic investigations.

What Vibration Analysis Brings to Engineering Diagnostics

Vibration analysis acts as a precision diagnostic tool for equipment and structures subjected to fluctuating loads. By studying vibrations in detail, we can uncover hidden issues that, if left unchecked, could lead to costly breakdowns or safety risks. At EDT, our process involves placing accelerometers on the equipment to capture real-time data on vibration frequency and intensity. This data enables us to create a “vibration fingerprint” that reveals the distinct frequencies and amplitudes unique to each case, allowing us to trace the issue back to its root cause.

Once we gather this data, we can identify the frequencies that correlate with the problematic vibrations, giving our clients a clear understanding of what’s happening and how to address it. Below are two examples of how this approach has resolved issues for our clients.

Case Study: Solving Noise Complaints in a Convention Center’s Cooling Towers

One of our recent cases involved a convention center experiencing disruptive noise levels stemming from their rooftop cooling towers. They’d already identified the noise source, but its cause and a solution remained unclear. The cooling towers were mounted on rubber isolators meant to dampen vibration. However, our analysis revealed that these isolators, while effective for lateral motion, couldn’t adequately address vertical vibrations. The result? A low-frequency “drumming” sound at around 30 hertz, disrupting classrooms on the floor below.

Using accelerometers, we measured vibration intensities at various points on the towers and on the building structure itself. The data showed that the rubber isolators were transmitting vertical vibrations directly into the building frame. To address this, the convention center replaced the rubber isolators with spring isolators. A follow-up vibration analysis confirmed the solution’s effectiveness, as the 30-hertz resonance was successfully dampened below the excitation level for the building frame.

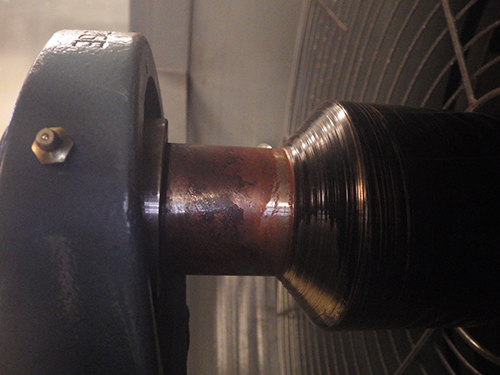

This case also uncovered a secondary issue: one cooling tower’s fan had worn bushings, which intensified vibrations. Identifying and resolving these issues saved the client from further disruptive noise, extending the equipment’s lifespan and improving the building’s environment.

Case Study: Extending Equipment Life in a High-Tech Building’s Ventilation System

In another case, in a high-tech building, the ventilation fans were experiencing frequent bearing failures, driving up maintenance costs. Our vibration analysis uncovered an imbalance in the fan assemblies, as well as issues with belt tension that had gone unnoticed during routine maintenance. This imbalance was causing uneven loads on the bearings, leading to premature wear.

By identifying these specific issues, we provided actionable guidance on rebalancing the fan assemblies and adjusting belt tension. This intervention not only resolved the immediate problem but extended the fans’ operational life, reducing ongoing maintenance costs for the building operator.

Not Just for Machinery: Broader Applications of Vibration Analysis

Vibration analysis often makes people think of machinery breakdowns or factory maintenance, but it’s far broader than that. In my experience, anything subjected to dynamic forces—from bridges to high-rise buildings to even something as unassuming as a traffic light pole—can benefit from vibration diagnostics. Each structure has its own “vibration signature” that can tell us a lot about its health and longevity, and it’s that level of insight that makes vibration analysis a valuable tool across industries.

As mentioned above, vibrations not only affect equipment, but they can affect the people exposed to vibrations. Structural resonance to a driving frequency is proven to cause discomfort – even nausea – to occupants when exposed to the resonance for periods at a time. Indeed, I experienced this first-hand, when awoken by shuddering in a ship I was monitoring at a frequency I knew was damaging the antenna I was brought onboard to monitor. Some of the best tools we have can be our own senses when analyzing vibrations.

At EDT, we see vibration analysis as part of a proactive approach to forensic engineering. For our clients in sectors like construction, industrial facilities, property management, shipping and shipbuilding, and power generation, addressing these issues with a targeted, data-driven methodology means operational continuity, occupant comfort, and fewer unexpected disruptions.

About the Author

Steven M. Lindholm P.E., P.M.P., NAMS-CMS, is a Consulting Engineer and Assistant Vice President at Engineering Design & Testing Corp. With over 40 years of experience in mechanical and marine engineering, Steve specializes in finite element analysis, failure investigations, and structural assessments.