Product Liability: Uncovering the Root Cause of an "Exploding" Circular Saw

When tools and machinery fail, the consequences can be severe—both for the individuals involved and for the manufacturers facing potential litigation. Attorneys specializing in product liability cases know that understanding the root cause of a product’s failure is crucial to building a strong case. At EDT Forensic Engineering & Consulting, we provide the detailed analysis needed to uncover these causes.

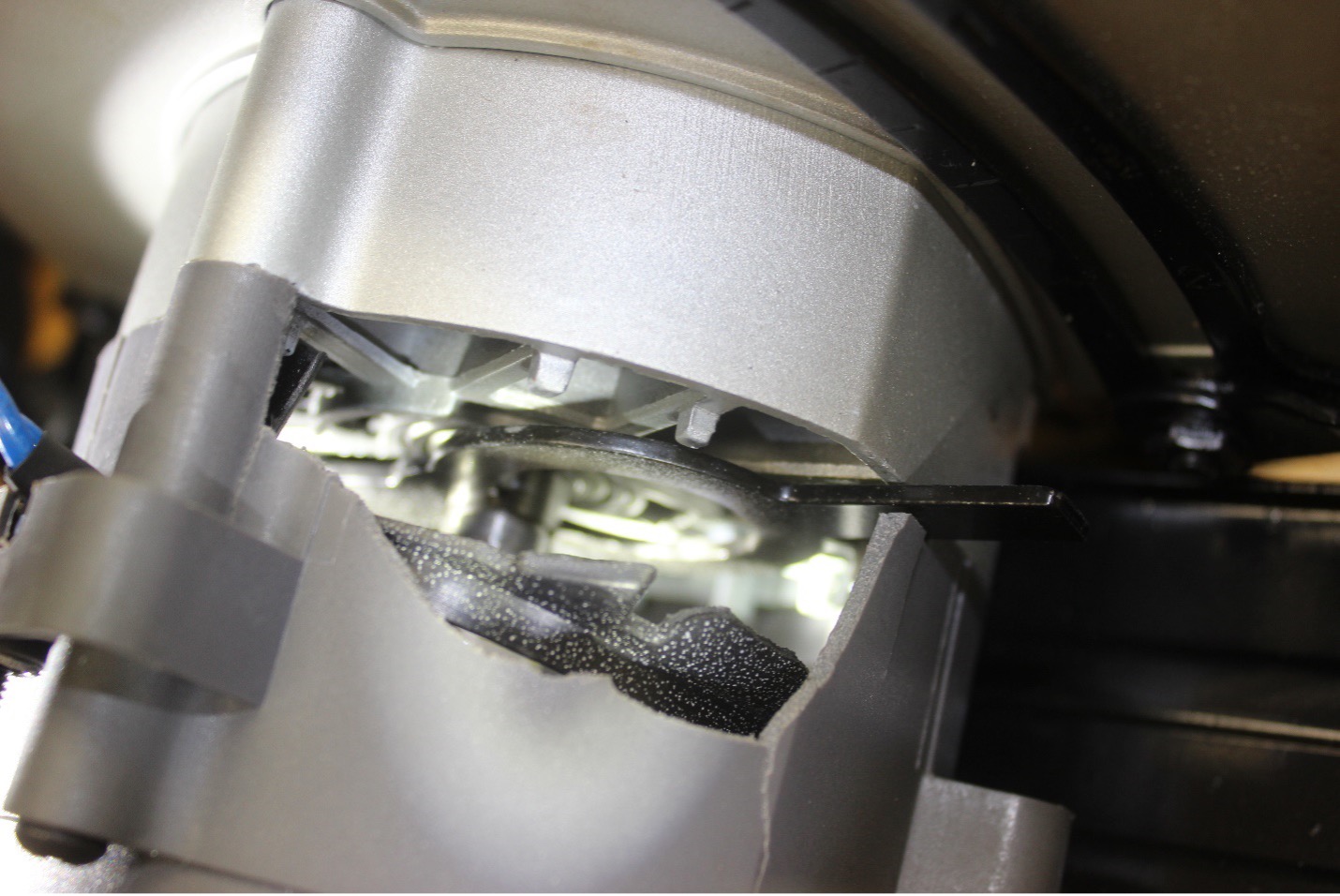

One such case involved a homeowner who purchased a circular saw from a well-known hardware store to complete a home remodeling project. The task was straightforward: cutting 2x4 lumber to size. The saw worked well to cut the lumber, at least until the final cut. The homeowner stated that when he had pulled the trigger switch, the saw did not start spinning. Moments later, the saw’s housing “exploded”, sending pieces of plastic flying and injuring the homeowner.

Investigating the Failure: Forensic Examination Begins

Faced with a potential product liability claim, the parties involved turned to EDT to lead the investigation to determine the cause of the saw malfunction. A joint examination was promptly scheduled with all stakeholders involved. To thoroughly understand the malfunction, the damaged saw was carefully disassembled and EDT procured an identical model for comparison, allowing for a precise analysis of the internal components and assembly.

The Findings: A Missing Spring Leads to Disaster

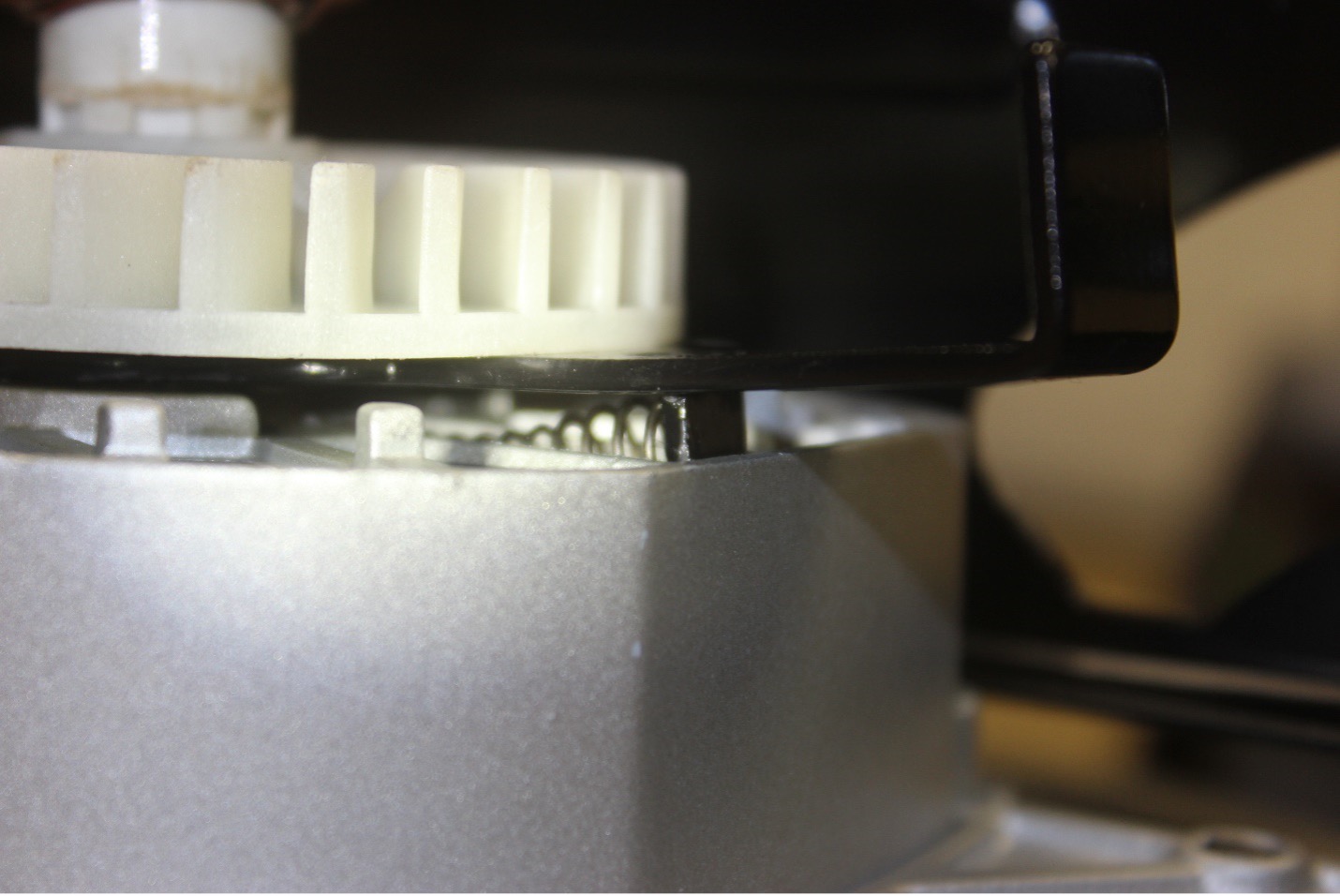

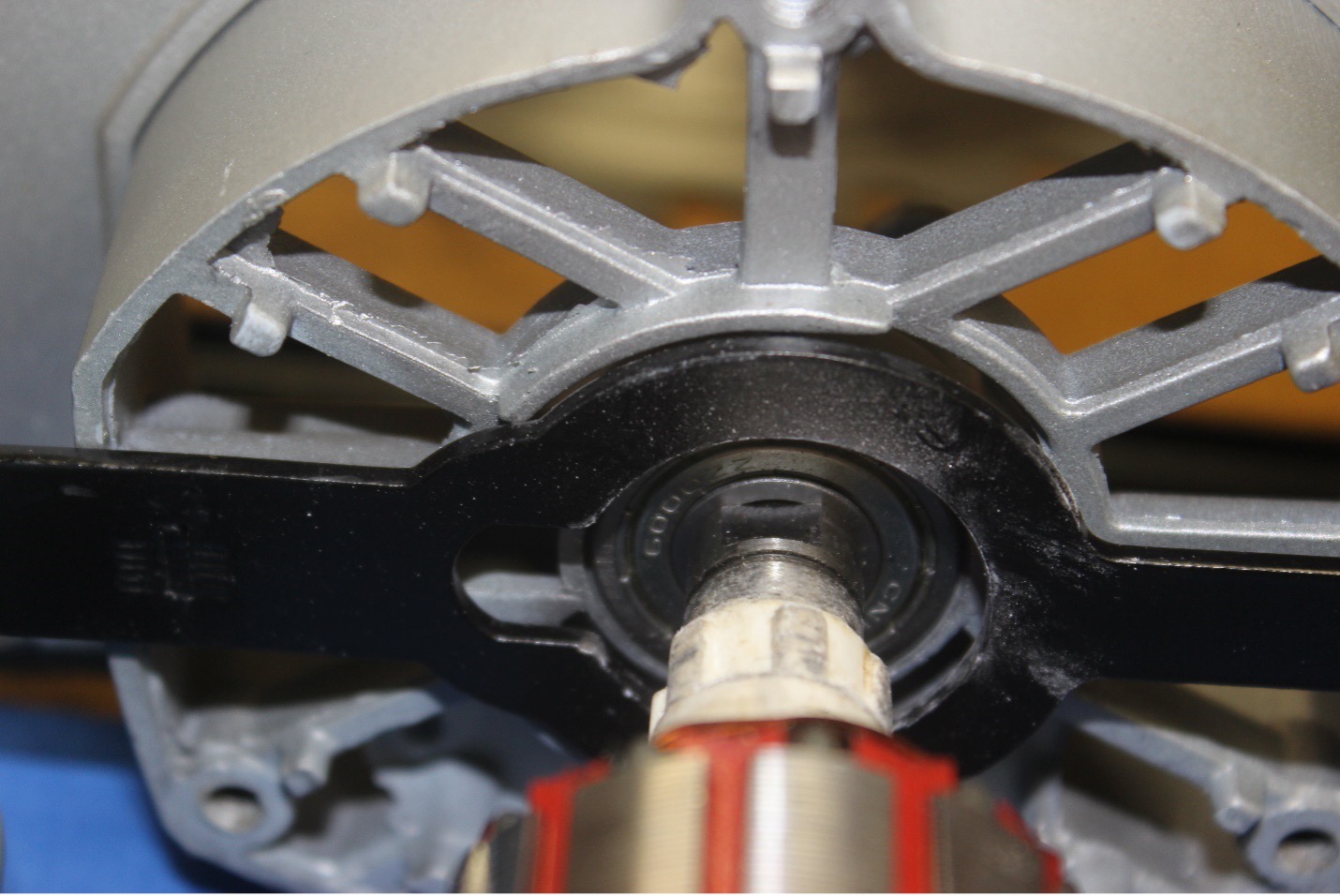

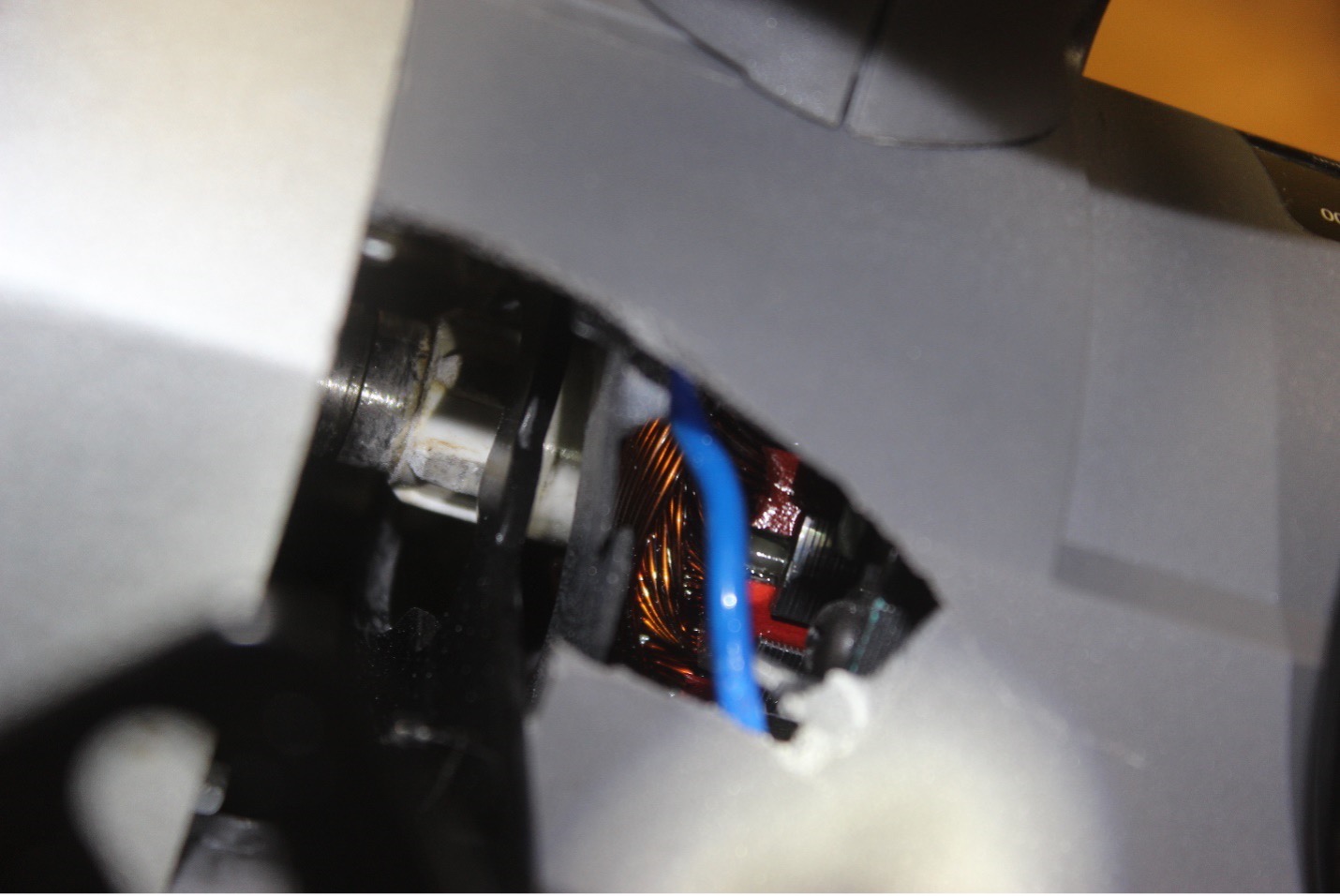

The investigation revealed a critical flaw in the saw’s design and assembly. To change the blade on the saw, a user must remove a nut from the motor shaft. This shaft, free to rotate, requires a locking mechanism to hold it in place during this process. The saw in question used a lock plate that engaged with flats machined on the shaft. Normally, a spring mechanism would push the lock plate back after the blade change, allowing the shaft to spin freely once again.

However, our examination uncovered that the spring was missing in the damaged saw. This missing component caused the lock plate to remain free to move, and by chance, the motor shaft stopped in alignment with the lock plate. When the homeowner pulled the trigger, the locked shaft transferred the full motor torque to the plastic housing, causing it to rupture violently.

Conclusion: Manufacturing Oversight as Root Cause

Our forensic analysis determined that the spring had never been installed during the saw’s assembly—a clear manufacturing oversight. The design of the saw was such that, had the spring been correctly installed, it could not have dislodged during normal use. This assembly error was the root cause of the saw’s failure and the resulting injury.

The Importance of Forensic Analysis in Product Liability Case

For attorneys managing the complexities of product liability cases, this incident underscores the critical need for thorough and timely forensic analysis. At EDT, we recognize that accurate, unbiased findings delivered within essential timeframes are key to effective case management. Our commitment to rigorous analysis and ethical practices ensures that the evidence we provide is reliable and actionable. With EDT as your partner, you can trust that our expertise will uncover the facts necessary to support your case, enabling you to make informed decisions based on solid evidence.

About the Author:

Kevin L. Brown, M.S., P.E., CFEI, CVFI, is a seasoned Consulting Engineer at EDT Forensic Engineering & Consulting. With over three decades of experience in mechanical engineering and a deep background in manufacturing systems, Kevin specializes in uncovering the root causes of machinery and product failures. His expertise is built on a foundation of rigorous analysis and a commitment to uncovering the truth, making him a trusted partner in complex product liability cases.