How to Prevent Wind Turbine Gearbox Failures: Expert Insights from a Forensic Engineer

As the renewable energy sector continues to grow, wind turbines remain a central pillar of the industry. However, behind their towering blades and energy production is a complex mechanical system that can be prone to failure.

As a forensic engineer, I’ve spent much of my career studying the failures of mechanical systems and equipment, from wind turbines to large engines. Over the years, I’ve learned that the key to preventing major breakdowns often lies in understanding not just how these systems work when things are running smoothly, but also what causes them to fail when they don’t.

In this blog, we’ll discuss some common reasons for wind turbine gearbox failure, how forensic analysis helps identify the root cause, and why early intervention is essential.

What is a Wind Turbine Gearbox?

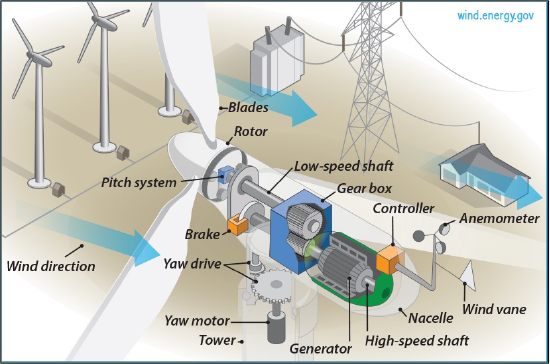

The gearbox is one of the most important parts of a wind turbine. It is responsible for converting the slow rotation of the blades into the high-speed movement needed to generate electricity.

Common Causes of Wind Turbine Gearbox Failures

Wind turbine gearboxes are prone to failure from stress, wear, and other factors. Having designed both high-speed and planetary gearboxes for various industries, I’ve seen firsthand how those factors can lead to issues.

Here are some of the most common causes:

- Improper Maintenance: Regular lubrication and monitoring are essential to avoid premature wear. Without proper maintenance, lubricants and critical components degrade at an accelerated rate as increased friction develops and often progresses to failure.

- Component Defects: Gearboxes need to be manufactured with precision, using durable materials. Any flawed or substandard materials/components may develop cracks/fractures or otherwise degrade under stress, leading to failure over time.

- External Damage: Wind turbines operate in harsh environments. Severe weather and other external factors such as those relating to debris or lightning strikes, can overload or otherwise cause damage to gearboxes that may progress to catastrophic breakdowns if left unchecked.

One of the earliest signs of potential gearbox failure is excessive vibration, which can be detected by the turbine’s condition monitoring systems which is able to pinpoint damage to the bearings, gears and other critical gearbox components. If caught early, these issues can be addressed often by the replacement of individual parts, reducing downtime and repair costs. However, if left unchecked, small issues can often grow into costly repairs and significant downtime, making timely response to detected issues one of the biggest concerns in wind turbine maintenance.

How EDT Investigates Wind Turbine Gearbox Failures

When a wind turbine gearbox failure occurs, a systematic forensic investigation is key to finding the root cause. At EDT, we use a structured approach to ensure thorough analysis and accurate reporting:

- Initial Site Visit: We gather data, examine the site, and talk to the technicians and others who work directly with the turbine to understand what may have gone wrong.

- Visual Examination: We inspect the damaged components to look for signs of wear, component defects, or external damage.

- Detailed Disassembly and Root Cause Analysis: In collaboration with a third party, we conduct a methodical disassembly, closely examining internal components and identifying root causes that contributed to the observed failure(s).

- Report Preparation: After a thorough investigation, we compile our findings into a comprehensive report that clearly explains the cause of failure. This equips insurers and operators to make informed decisions about coverage and repairs.

Early intervention by forensic engineers is critical a successful investigation. The sooner we get involved, the more accurate we can be in gathering data and better our understanding of what went wrong. This is especially important in wind turbine gearbox failures, where minimizing downtime and financial loss is crucial.

Lessons from Other Mechanical Failures

While wind turbine gearbox failures are a large focal point in the renewable energy sector, they aren’t the only large mechanical systems prone to failure. I’ve also spent years analyzing failures in large engines—like those found in gensets, compressors, pumps at fracking/energy installations—and other loss sites where damage to equipment is often measured in millions of dollars. While they differ from gearboxes in many ways, engines often experience break downs as the result of similar underlying mechanisms as those experienced by wind turbine gearboxes, including but not limited to mechanical wear, lubrication issues, component defects, and issues arising from improper assembly.

For example, my forensic travels have taken me all across North America and even overseas to assist in the root cause analysis of large engine failures. The level of detail for these investigations is often times quite comprehensive, covering everything from careful inspection of an engine’s individual components to a thorough review of maintenance records and operational data. Being well acquainted with the complexities of large engines found in power generation, oil and gas and other industries often proves helpful in providing insight into the challenges faced in wind energy. These industries involve intricate and at times complex mechanical systems that rely upon constant oversight and maintenance to avoid costly breakdowns.

Preventing Future Wind Turbine Gearbox Failures

Prevention of wind turbine gearbox failures is the product of a combination of proper maintenance, early detection, and thorough analysis of collected data.

While advances in wind turbine gearbox and drivetrain design have reduced failure rates, a growing number of aged wind turbines remain in operation, increasing the need for the completion of a detailed root cause analysis.

For companies in the renewable energy sector, working with a forensic engineer who understands the nuances of these systems can make all the difference in resolving claims efficiently and accurately.

At EDT, our team of experts is ready to assist with investigations and help operators make informed decisions to minimize downtime and financial loss. Whether it’s a wind turbine gearbox, a large engine, or a solar installation, understanding the root cause of a failure is the first step to preventing it from happening again.

About the Author

Chris S Spies, P.E., is a consulting engineer at EDT, specializing in the forensic analysis of mechanical, vehicle, and industrial systems and equipment failures. With a strong background in engine assembly and design of compressors, gear drives, and complex mechanical systems, Chris provides expert insights into the causes of equipment failures to help clients make informed decisions.