Why Pipe Ruptures Aren't Always Where You Think

As winter approaches, many of us brace for the challenges that freezing temperatures can bring to our homes and businesses. One common issue is pipe ruptures due to freezing. A frequent misconception I've encountered is that the location of a pipe rupture is always where the pipe froze. In reality, the rupture point isn't necessarily the same as the freeze point. Understanding this phenomenon is crucial for accurately diagnosing issues and preventing future problems.

The Misconception About Pipe Freezes

When water inside a pipe freezes, it expands and creates a blockage. This blockage doesn't typically cause the pipe to burst at that exact spot. Instead, the expanding ice increases pressure in the unfrozen sections of the pipe. If the pressure becomes too great, the pipe can rupture at a point away from the freeze, often at a weaker section. This means that the visible damage may be some distance from the actual problem area.

Real-World Examples

Example 1: Hydronic Pipe Freeze in a Boiler System

In one recent case, a home with a boiler heating system experienced a leak due to a hydronic pipe that had ruptured from freezing. A third-party engineering company conducted a heating analysis and concluded that the heating system wasn't operating, leading the homeowner's insurance company to deny coverage. The homeowner insisted that heat was maintained but thought the thermostat had failed.

We were brought in to provide a second opinion. I evaluated the thermostat and conducted a separate heating analysis. Our findings showed that the thermostat was functioning properly, but the average indoor temperature was lower than what was claimed. Further examination revealed that some pipes were located along uninsulated exterior walls, exposing them to freezing temperatures despite the heating system being operational.

Conclusion: The pipe froze due to its location along an uninsulated exterior wall, not because of a thermostat failure. The rupture occurred where the pressure buildup exceeded the pipe's capacity, which wasn't necessarily at the point of freezing.

Example 2: Furnace Trip Due to a Clogged Air Filter

In another case, a homeowner had recently purchased a house but hadn't moved in yet. The home was heated by a furnace. A leak occurred from a bathroom sink pipe due to freezing. Our heating analysis indicated that the indoor temperature was too low to prevent freezing.

Upon examining the furnace, we discovered it had tripped due to excessive internal temperatures caused by a clogged air filter. This prevented the furnace from operating as intended. However, the homeowner had set the thermostat to maintain heat, unaware of the furnace issue.

Conclusion: The pipe froze because the furnace wasn't heating the home, not due to negligence on the homeowner's part. The rupture occurred at a vulnerable point in the plumbing system, not at the furnace or the point of freezing.

Example 3: Unexpected Freeze in a Commercial HVAC System

In a commercial building, a hot water coil in an HVAC system froze and leaked during the summertime. This was puzzling because freezing isn't expected in warm weather.

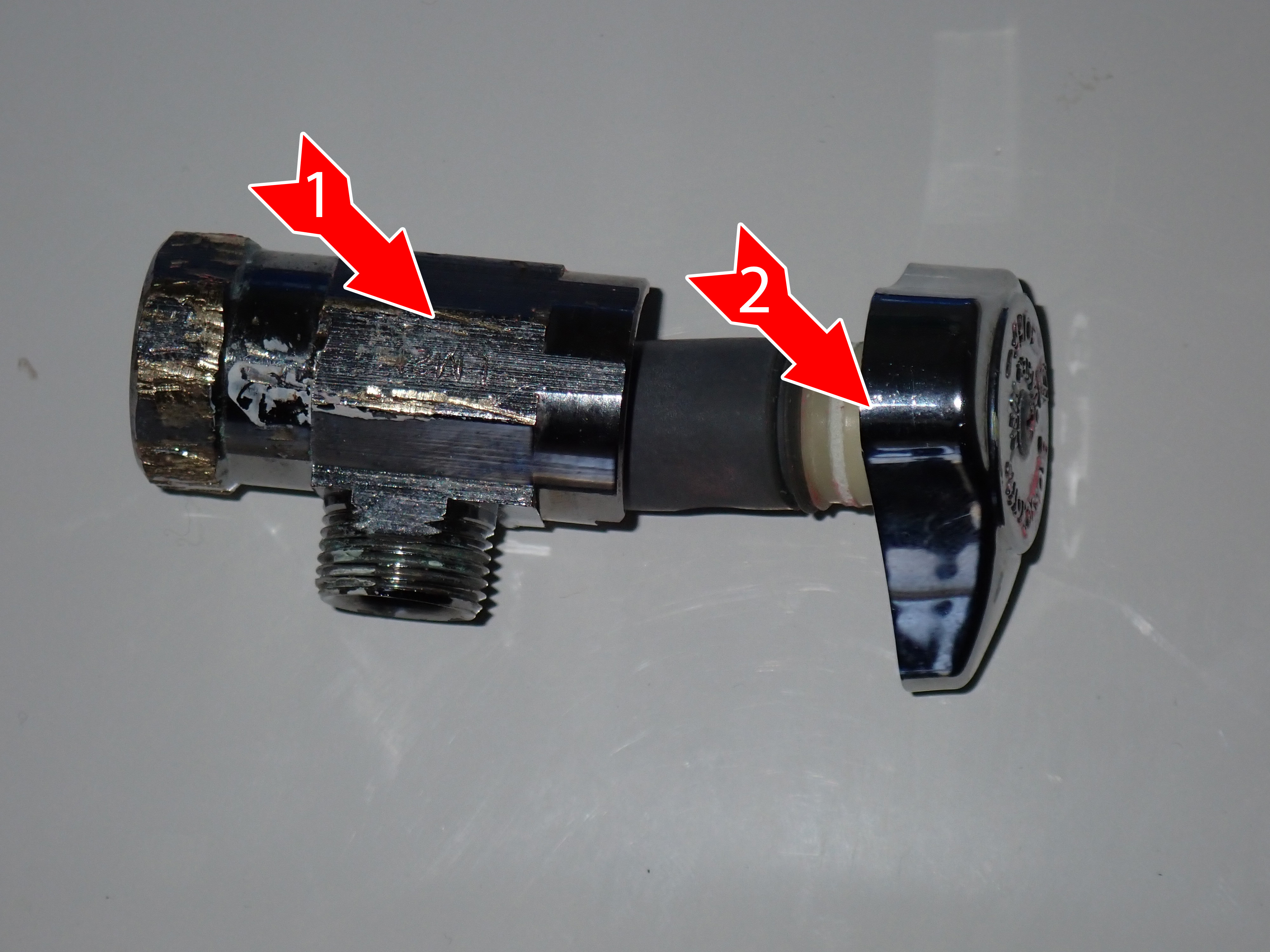

We evaluated the HVAC system and found that a solenoid valve controlling the flow of refrigerant was stuck open. This caused continuous cooling near the hot water coil, leading to temperatures low enough for the coil to freeze and eventually leak.

Conclusion: The freeze occurred due to a malfunctioning solenoid valve affecting the area around the hot water coil. The rupture happened at the coil, but the root cause was elsewhere in the system.

The Importance of Thorough Investigation

These cases highlight that the visible rupture isn't always at the point where the problem originated. Misunderstandings can lead to incorrect conclusions about the cause of damage. A detailed investigation is essential to uncover the true sequence of events leading to a failure.

Our Approach at EDT

When we're brought in to investigate a pipe rupture, our process typically involves:

- Gathering Information: Contacting the client to understand the details of the incident.

- Conducting Background Research: Learning about the specific system or equipment involved.

- Site Examination: Performing a thorough on-site inspection of the affected areas.

- Collaborating with Colleagues: Consulting with other engineers if the case involves multiple disciplines.

- Analyzing Findings: Evaluating all data collected to determine the root cause.

- Reporting: Providing a detailed report outlining our findings and conclusions.

By methodically working through each step, we aim to accurately identify why something happened, not just what happened.

Understanding Causes, Not Just Symptoms

Recognizing that ruptures can occur away from the freeze point helps us:

Identify the True Cause: Avoiding assumptions ensures we don't overlook critical factors.

- Provide Accurate Assessments: Our clients rely on us for precise information to make in

- Assist in Resolution: Understanding the actual cause can influence insurance coverage decisions and repair strategies.

Pipe ruptures due to freezing are more complex than they might appear. The rupture point may not be where the pipe froze but could be elsewhere due to pressure changes in the system. Thorough investigations are necessary to uncover the real reasons behind such failures. At EDT, we're committed to digging deep to find the root cause of mechanical failures. Our detailed approach ensures that all factors are considered, providing clarity for homeowners, insurance companies, and legal professionals.

About the Author

John M. Rophael, P.E., is a Consulting Engineer with Engineering Design & Testing Corp., specializing in mechanical and piping systems. With experience in failure analysis, damage assessment, and technical investigation, John brings a meticulous approach to uncovering the causes of mechanical failures.