The Testing Technique That’s Improving Solar Damage Assessment for Insurance Claims

Solar farms are subject to the hazards of extreme weather, including hailstorms that can cause extensive, costly damage. Among the many severe incidents, hailstorms were responsible for over $300 million in damage to solar fields in Texas in the summer of 2022. When large-scale losses like these occur, insurance companies need an accurate assessment of the extent of the damage as well as the cause.

Forensic engineers can aid in this critical process by using a variety of testing techniques to evaluate solar panel damage. While AI-powered drone-based infrared thermography is touted as one of the best solutions, its effectiveness and efficiency is subject to limitations. Leading engineers are now considering the use of electroluminescence (EL) testing to identify the extent and cause of solar panel damage in the aftermath of a storm.

How EL Testing Aids Solar Farm Investigations

The newest EL testing equipment combines a power supply, a modified short-wave infrared camera, and specialized software to help forensic engineers identify certain types of failures in solar panels. The power supply applies a current force to the PV cell, the camera captures the image within the correct infrared band range, and the software filters the image to assist the test operator in assessing the findings.

EL testing is highly conducive to finding microcracks in solar panels, which are cracks in the cell that are not visible with the naked eye or detectable by touch. Even if the solar panel glass itself doesn’t appear to be cracked, the cell could have sustained damage from a variety of causes, including severe weather, manufacturing stresses, or poor handling during shipping and installation. Microcracking is one of the leading types of solar panel damage.

Some forensic engineering companies are applying EL testing to assess solar farm damage with a high degree of granularity and accuracy, even across facilities with hundreds of thousands of panels. It’s a cost-effective approach to identifying the type, cause, and extent of the damage.

Where EL Testing Offers Value in Solar Damage Assessments

When solar panels sustain damage, it’s important to distinguish between manufacturing problems, installation issues, and weather-related incidents. El testing is well-suited to do that.

Some of the anomalies that EL detects are likely attributable to manufacturing issues. For example, V-shaped cracks and dark regions around the panel busbars often result from soldering problems, while blotches that occur in repeating patterns can be indicative of cell processing contamination.

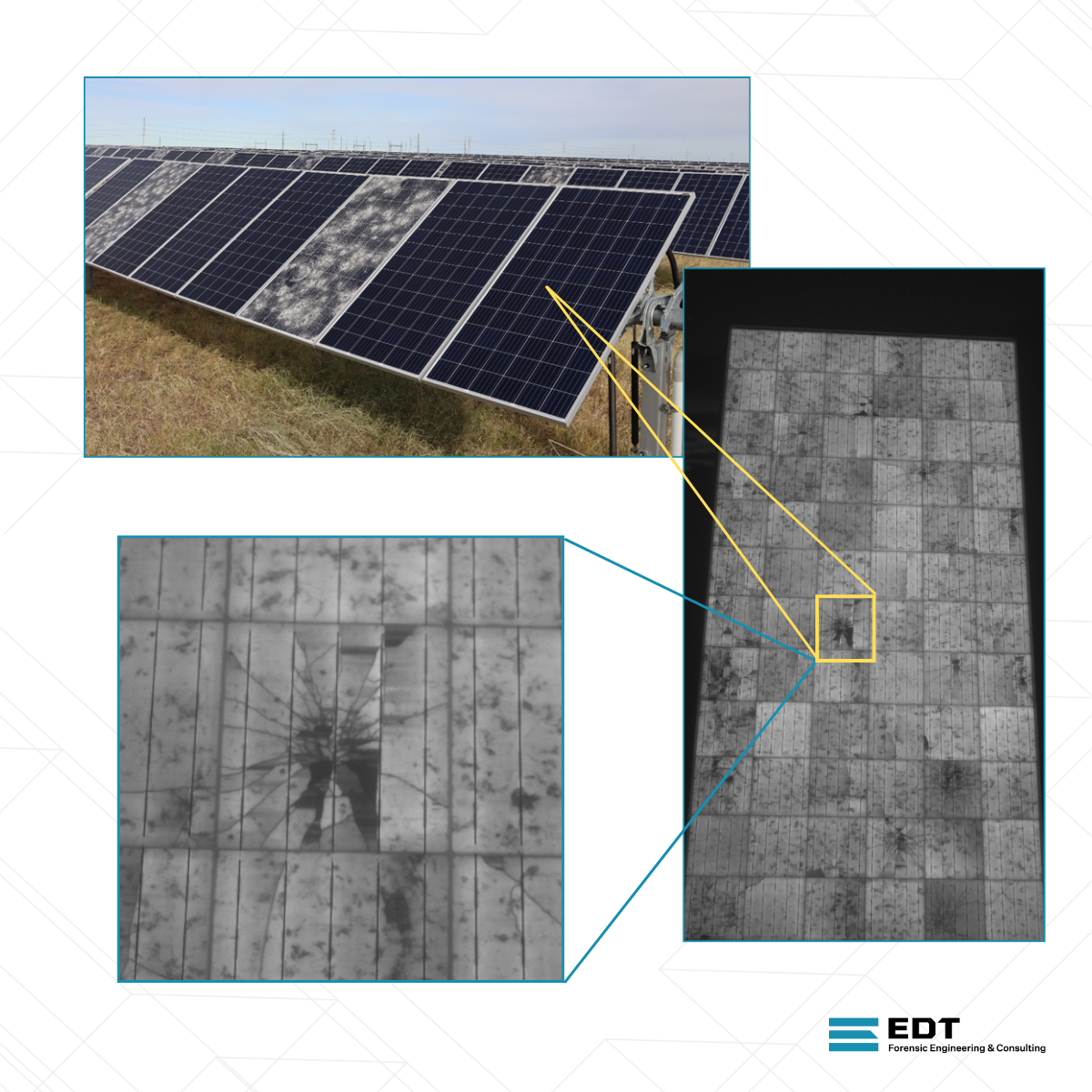

EL testing also can spot problems that occurred in the field, either during or after installation. For instance, X-shaped “crow’s feet” cracks suggest the panel sustained a rear-side impact, which can happen if cable connectors swing into the panel, or it is dragged across the ground.

The Pros and Cons of EL Testing in Solar Panels

EL testing is very effective at detecting cracks, especially compared to other methods available for solar panel damage assessment. It also overcomes the limitations inherent in some testing alternatives. For example, UVF testing is capable of detecting solar cell cracks; but not all solar modules emit UVF, so this method isn’t widely applicable. UVF testing also requires sunny weather, which can slow the assessment investigation timeline. In contrast, EL testing isn’t weather dependent, though it is done at night to ensure image accuracy.

The fact that EL testing can be done in the field now is another advantage. In the past, it was only possible to conduct EL testing on solar panels in the lab, adding time and expense to the process. The option to perform EL testing in the field—and obtain results in real time— strengthens the case for using this method to evaluate solar farm damage in certain circumstances.

As with all methods, EL testing has limitations. For example, it does not always provide clear, quantitative conclusions on long-term module performance and is potentially costly to conduct. However, a strategic approach can help to mitigate the expense.

Forensic engineers can spot test a portion of the affected panels to determine the type of damage, as well as its likely cause and extent. Following an industry-accepted standard for the number of panels to test with a high degree of confidence, EDT evaluated a sampling of panels across a facility with thousands of modules. Every unit tested had sustained damage likely caused by a hailstorm.

Trust EDT for Solar Damage Support

When the damage to a solar farm has the potential to total millions of dollars, and disputes arise about which party is liable, it’s critical to assess the damage accurately and on a fast timeline.

We bring the real-world experience and deep knowledge of renewables to evaluate the situation, select the most appropriate testing method, conduct the testing in the field or the lab, analyze the results, and provide a data-based opinion on the damage type, cause, and extent. Our highly experienced forensic engineers also provide expert testimony for investigations that go to trial.

Contact EDT to learn how our forensic engineers can apply advanced diagnostics technology to support your solar farm damage investigation.

About the Author

Britton C. Hager, P.E. is a consulting engineer with our Cherry Hill Office. Mr. Hager provides consulting in the areas of design and performance of electrical power distribution, transmission, and generation, including fire origin and cause analysis, scope of damage, and repair/replacement economic and technical feasibility analysis. His areas of expertise also include electrical systems and equipment performance during fault and unbalanced conditions, as well as analysis of arc flash events, and lightning strikes.